With the continuous development of aerospace technology, the leakage problem has become a key factor that must be considered in the design and manufacture of aerospace products. More and more people pay attention to it. The leakage rate detection of related electronic components has attracted great attention of researchers. At present, the leakage detection technology is mainly applied to sealed relays and integrated circuit enclosures.

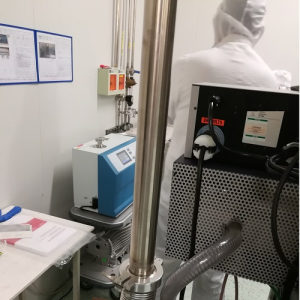

Helium mass spectrometer leak detector can be used to measure the leakage rate of sealed relay conveniently. Adopt appropriate leak detection methods for different products.

At present, the leakage rate detection of military sealed relay is mainly based on the 112 test program of GJB360A-96. The conditions and steps for leak detection of sealed relay are clearly specified in the experimental procedure. This time, we mainly discuss that the back pressure leak detection belongs to the fine leak detection step.

The back pressure leak detection method of relay is generally divided into three steps: 1. Add helium pressure: put the tested relay into the helium filled pressure tank; 2 Purification: take the relay out of the pressure tank and blow the helium adsorbed on the relay surface with nitrogen or air flow. 3 Leakage detection: put the relay into the leakage detection box of the leakage detector for detection. If the relay has leakage, the helium pressed into the inner chamber will enter the leakage detector through the leakage hole, and the leakage rate will be displayed on the instrument.

It is clearly specified in GJB360A-96 that the selected pressurization pressure, pressurization time and maximum residence time shall make the specified leakage rate of the tested sample greater than the minimum detectable leakage rate of the leak detector. When the leak is too large, the helium that is pressed in during helium pressurization will be evacuated before leak detection, so no helium can be picked up. The fluorine oil method can be used for rough leak detection to check the existence of large leaks.